Oil and Emulsion Mist, Aerosols

In industrial environments such as CNC machining, metal cutting, grinding, and stamping, oil-based coolants and emulsions are frequently used. These processes generate oil mist, emulsion mist, and aerosols, which pose serious challenges for air quality, worker health, and equipment longevity.

Efficient mist collection systems are essential for capturing submicron particles, improving indoor air quality, and ensuring compliance with health and safety regulations (such as OSHA and NIOSH standards).

✅ Why Mist & Aerosol Filtration Matters

-

Protects Operator Health – Prevents inhalation of harmful airborne droplets

-

Improves Workplace Air Quality – Reduces fogging, odors, and residue build-up

-

Preserves Equipment Life – Keeps sensitive electronics and machinery clean

-

Reduces Fire Risk – Minimizes flammable mist concentrations

-

Ensures Regulatory Compliance – Meets air quality and emission standards

🛠️ Common Applications

-

CNC machining centers

-

Turning, milling, and drilling operations

-

Grinding and polishing stations

-

Metal stamping and forming

-

Die casting with oil-based lubricants

Available Filter Technologies

-

Coalescing Filters – Capture and drain oil droplets from the air

-

Electrostatic Precipitators (ESP) – Efficient for submicron aerosols

-

HEPA/ULPA Filters – For critical environments with high filtration needs

-

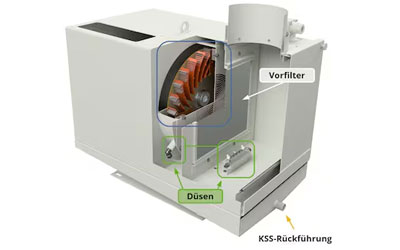

Centrifugal Mist Collectors – For large mist volumes and oil recovery

.png)